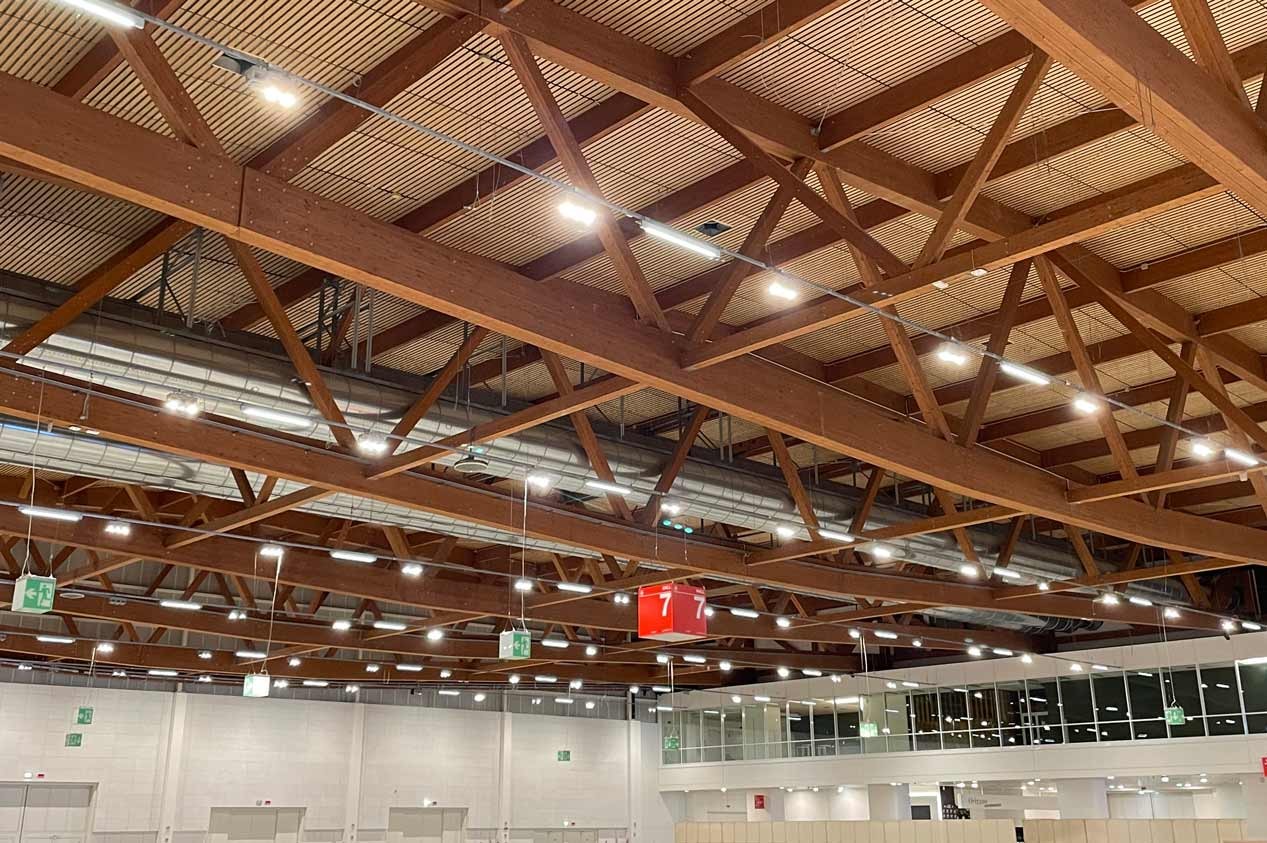

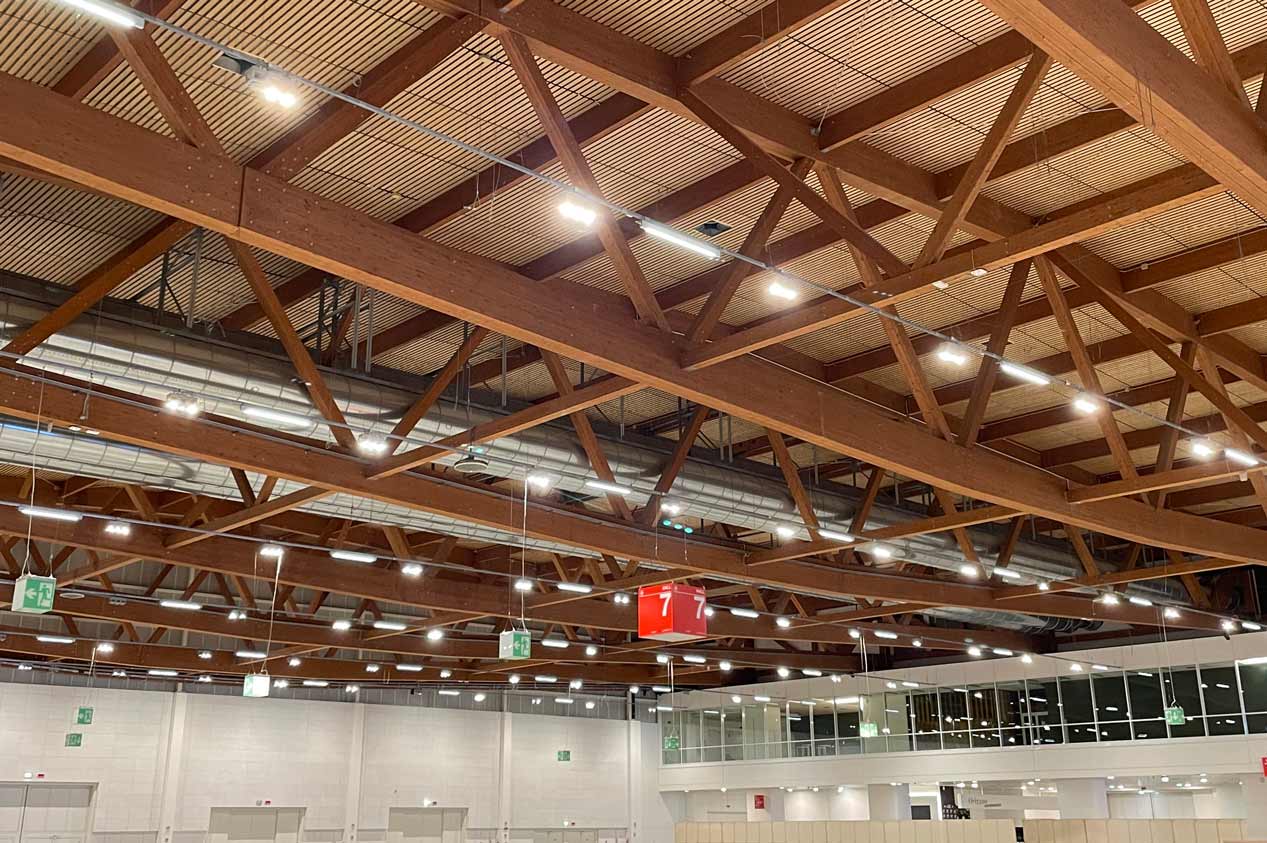

Use of property: exhibition centre

Use of MyMeter: prevention in re-roofing

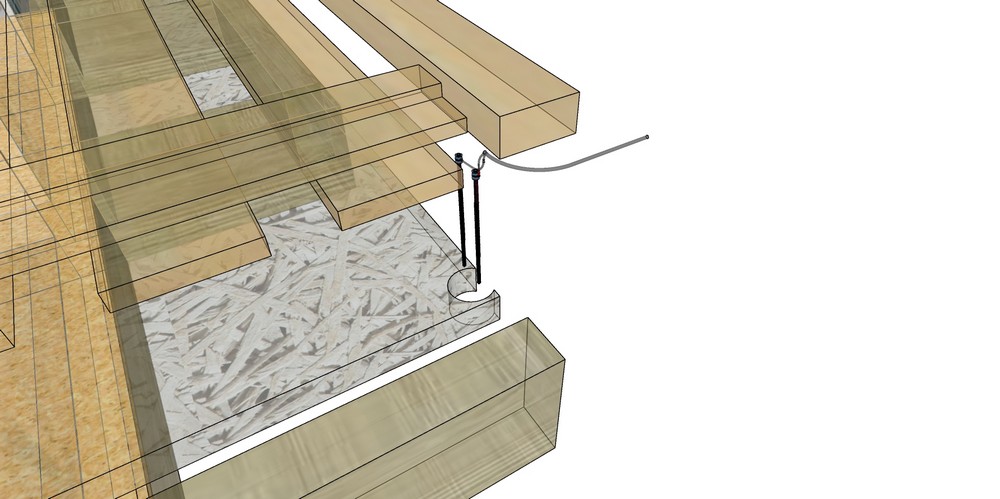

Technology: Next Panel by Wolf System

Year: 2021

- Location: Vicenza - Italy

Description

During the refurbishment of the roofing of the exhibition halls, the Exhibition Centre of Vicenza has requested the installation of a humidity monitoring system, in order to prevent problems of reduced durability.

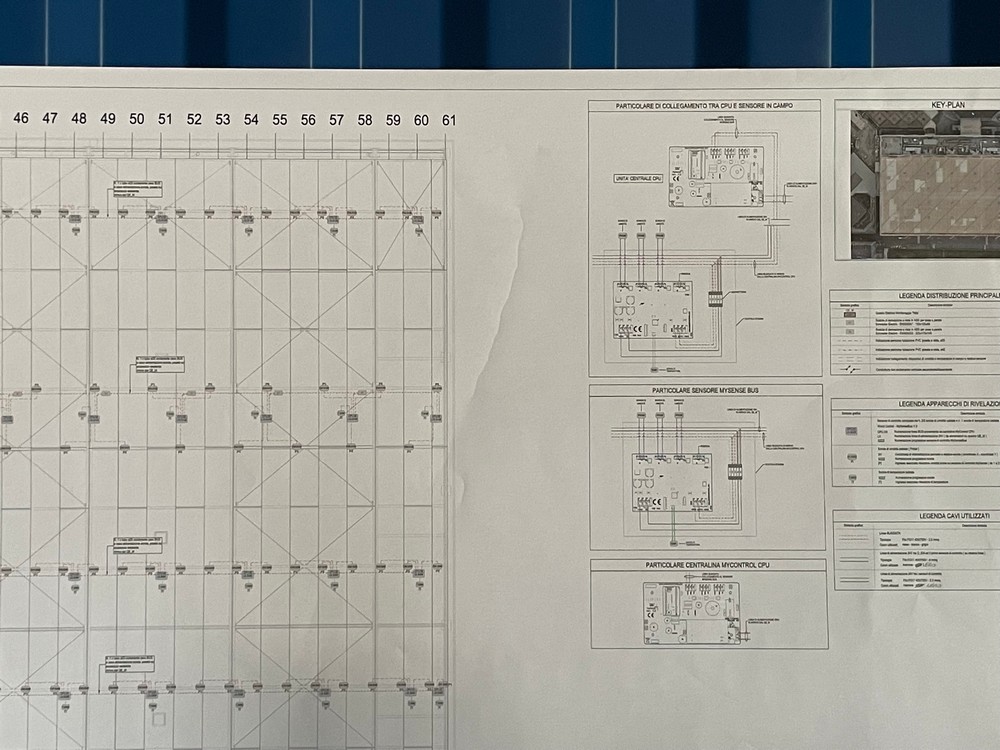

Given the size of the roof (about 11,600sqm) and the peculiarity of the intervention, it was fundamental to carry out a careful design study of the correct positioning of the sensors, in collaboration with the client.

The project in numbers

- 144 meters of cover length

- 2 pitches of 40 meters each

- about 11600 square meters of total area

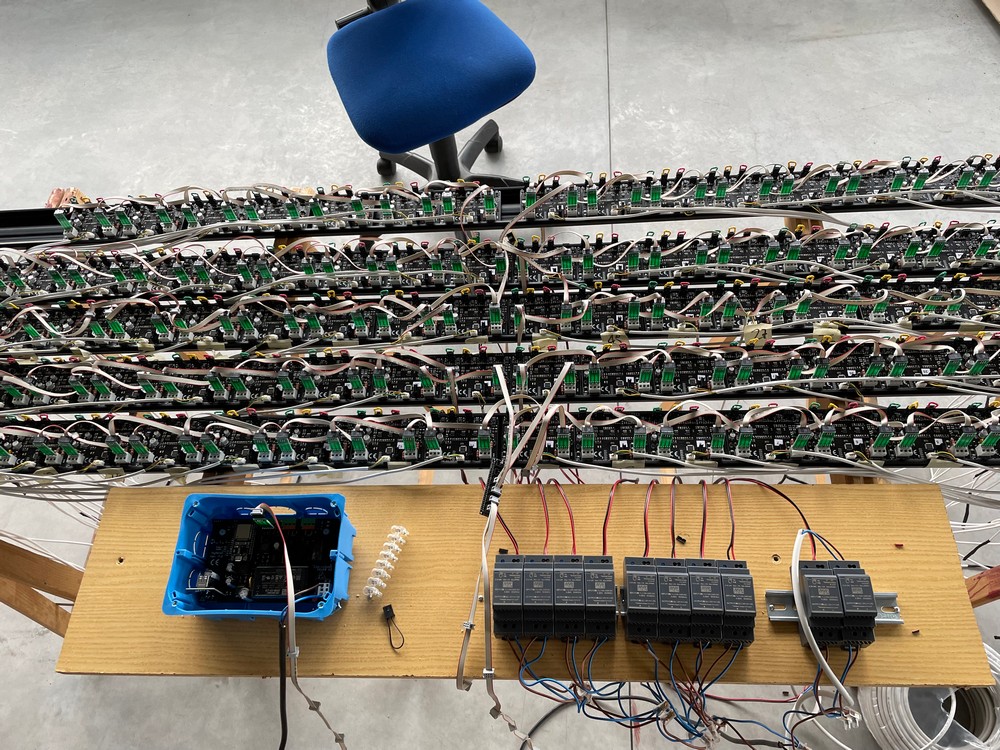

- consisting of 366 prefabricated panels in the company

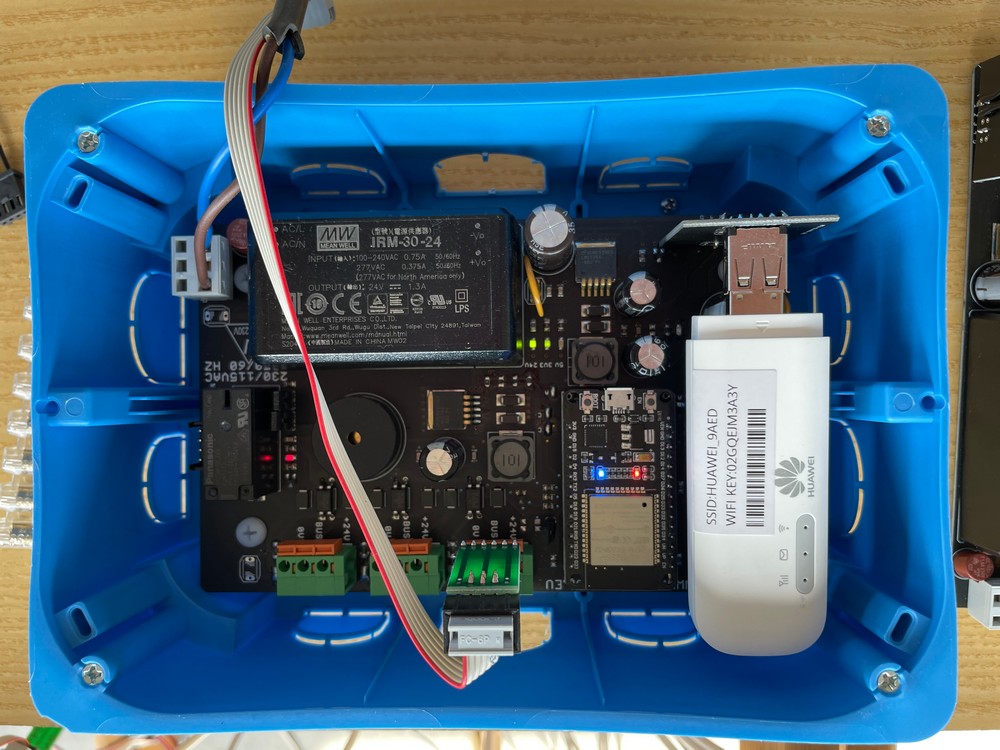

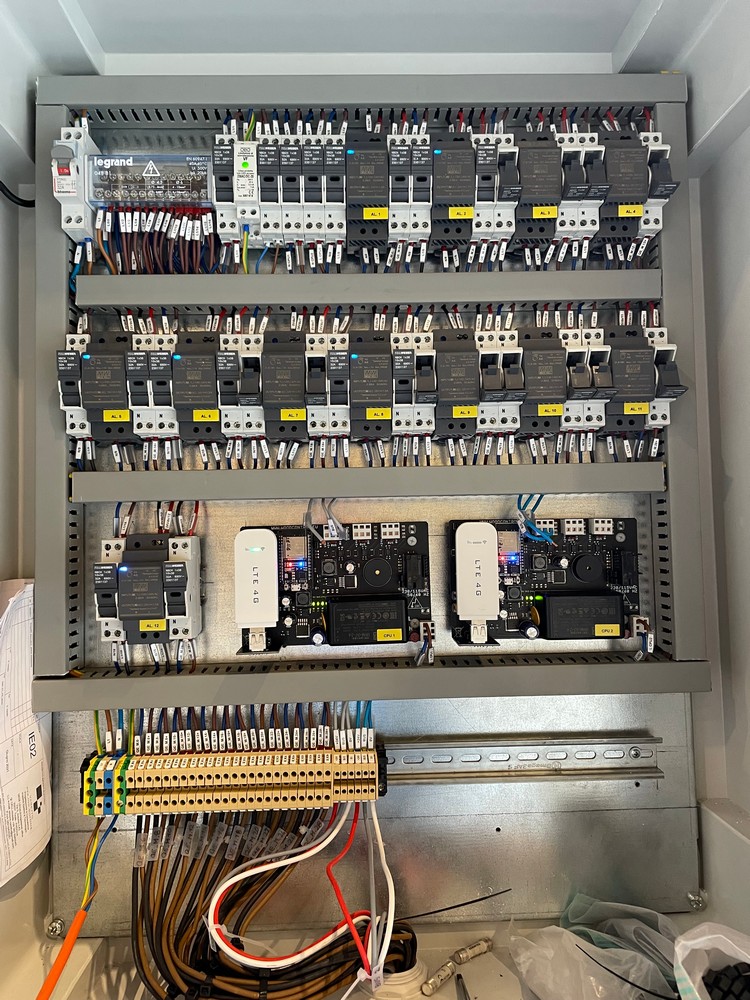

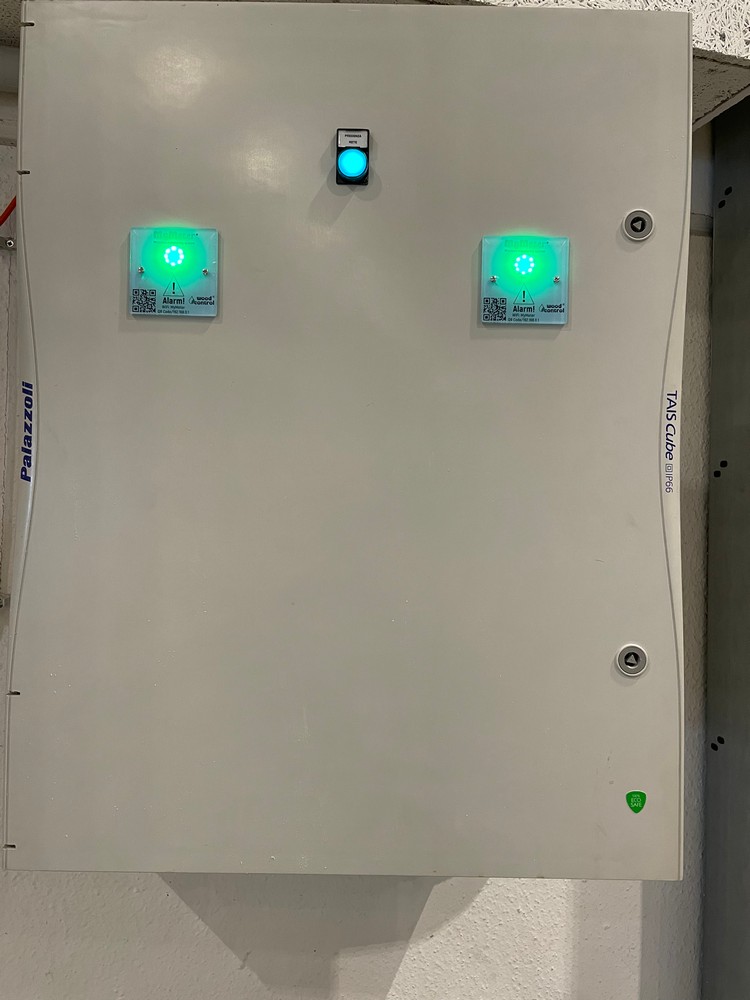

- 2 MyMeter MyCPU100 control units used

- 126 MySenseBus sensors installed (63 per pitch)

- 126 temperature probes

- 366 probes of humidity

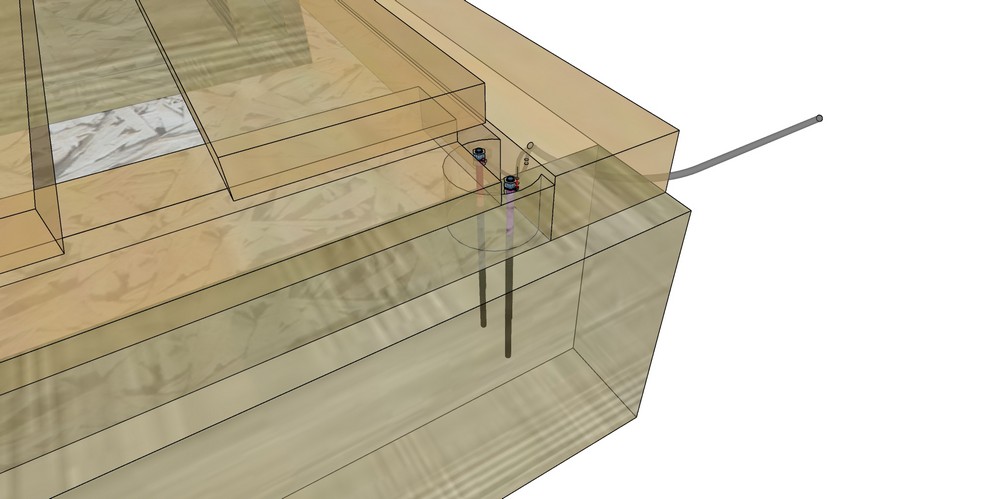

- 732 electrodes fixtures in wood

- 1956 meters of probes

- 8900 meters of wiring

Features

The monitoring of the coverage of the Vicenza Fair is unique in various aspects and the solution adopted has been studied and designed for this specific case, starting from the company’s know-how.

Given the extraordinary dimensions of the roofing and the structure of the same, the need of the client was to install an effective monitoring system, making an efficient economic investment, optimizing the number of sensors and the positioning of the reading points.

The idea that industrial buildings can reach large dimensions has led us to try to optimize costs, increasing the elements less impacting. The solution we worked on was basically to evolve the standard sensors from the ability to manage two reading points, up to four.

In this way, the number of sensors - technologically more complex and expensive elements - has been reduced in favor of increasing the reading points, consisting of electrodes and wiring.

From the analysis of the technical drawings, it was decided to ideally divide the roof into two equal pitches with an area of 5760 square meters (144 x 40 meters).

Each pitch has been equipped with a MyCPU100 control unit that collects data from the 63 MySenseBus sensors located in that portion of cover.

In total, there are 126 sensors, which monitor the state of the cover through 492 probes, of which 366 reading points for humidity and 126 for temperature. The count shows that not all sensors have been activated the 4 available humidity probes.

About 9000 m of cable were needed for the wiring of the plant, of which about 6000 were needed to connect the 126 sensors to the power supplies and another 3000 meters of signal cable between data and control unit.